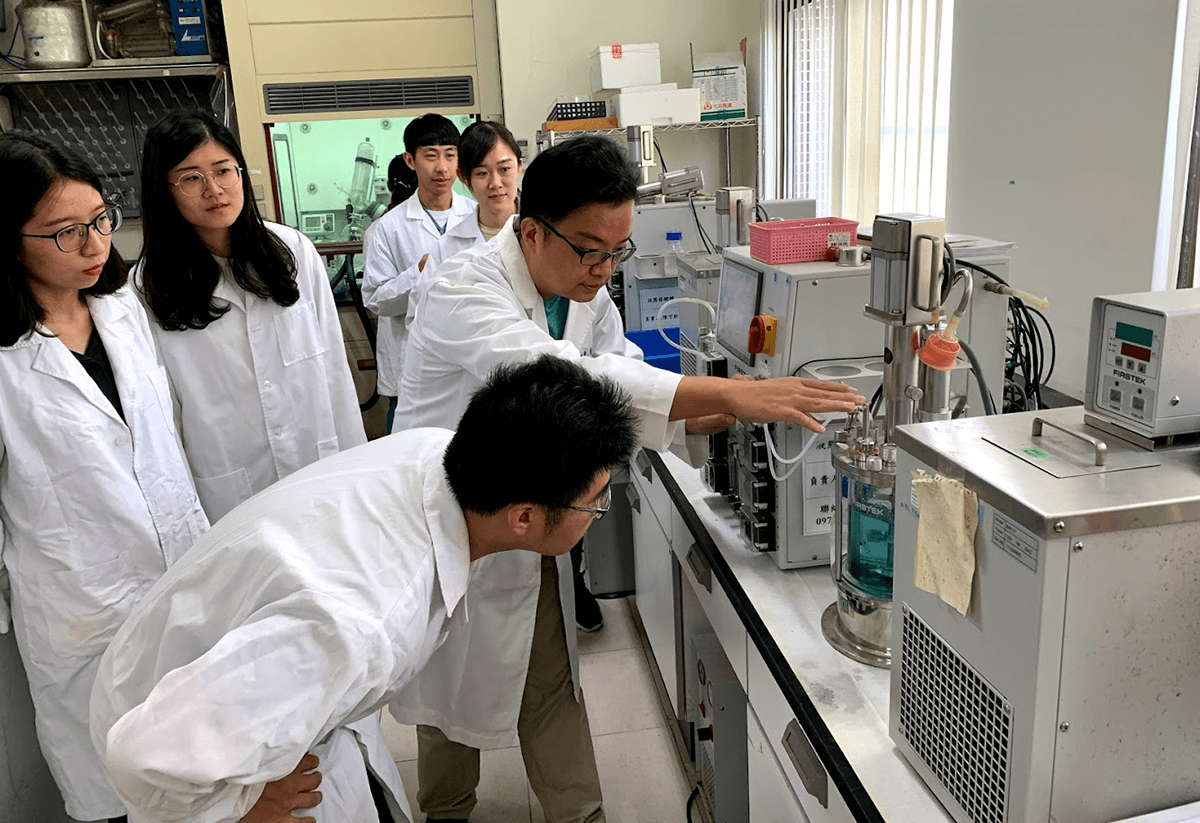

Precision Fermentation – Prof. Cheng (center, pointing).

Chenopodium formosanum (Djulis), a pseudo cereal plant, native to Taiwan, is known to possess numerous nutrients and antioxidants. A research team at NTU’s Institute of Biotechnology has demonstrated that the nutritional values of Djulis could be enhanced by bioconversion.

The team led by Prof. Kuan-Chen Cheng and Prof. Shu-Han Yu, together with Ph.D. candidate Chen-Che Hsieh, successfully designed a solid-state fermentation system to induce large-scale fermentation of Djulis sprouts. By utilizing the fungus, Rhizopus oligosporus as the fermenting agent, the team compared bioactive and nutrient components obtained from both a traditional plate fermentation and a bioreactor.

Using untargeted analysis techniques, such as HPLC-DAD and UHPLC-ESI-MS/MS, the team evaluated many small molecular metabolites from fermented Djulis sprouts. Additionally, two-dimensional gel electrophoresis and LC-MS/MS (Orbitrap Elite ETD) were employed to isolate and characterize the proteomics of the samples. Upon identifying peptides in the fermented products, the team used AnOxPePred and BIOPEP-UWM to screen for antioxidant properties and other potentials.

Ph.D. candidate Hsieh found that fermentation in a bioreactor produced more nutrient composition, free peptides, phenolic compounds, isoflavones, antioxidant capacity, and enzymatic activity than did traditional plate fermentation. Additionally, over twenty new metabolites were discovered in the bioreactor compared to its plate fermentation counterpart.

Prof. Yu consolidated her academic expertise and industry experience by analyzing proteomic patterns of samples from the bioreactor system and identified seven different peptides after blasting with the Uniprot database. Using her approach, the team was able to identify dipeptidyl peptidase IV (DPP IV) and angiotensin-converting enzyme (ACE) inhibitor, the two peptides that showed high free radical scavenging scores and bioactive properties.

Prof. Cheng integrated 20 years of research experience in microbial processing to develop a fermentation system that can enhance the antioxidants and nutritional values of Djulis sprouts as well as other food products. He concluded: “A scale-up fermentation system like a bioreactor offers many advantages compared to plate fermentation. Using this technique, we can obtain products that can be utilized as food supplements and other nutraceutical compounds. This is the future of food production.”

Abstract graph.

BF Fermentation – Prof. Cheng (first left) and Ph.D. candidate Hsieh (first right).

Fermented Djulis sprout in the solid state bioreactor.

Members of the Precision Fermentation Lab.