Students discussing smart manufacturing concepts.

A modern smart manufacturing system is typically structured into five core layers: the device layer, control layer, network layer, application layer, and decision layer. As shown in Figure 1, these layers are interconnected by enabling technologies, such as digital twins, the Industrial Internet of Things (IIoT), control systems, big data analytics, artificial intelligence (AI), and cloud and edge computing.

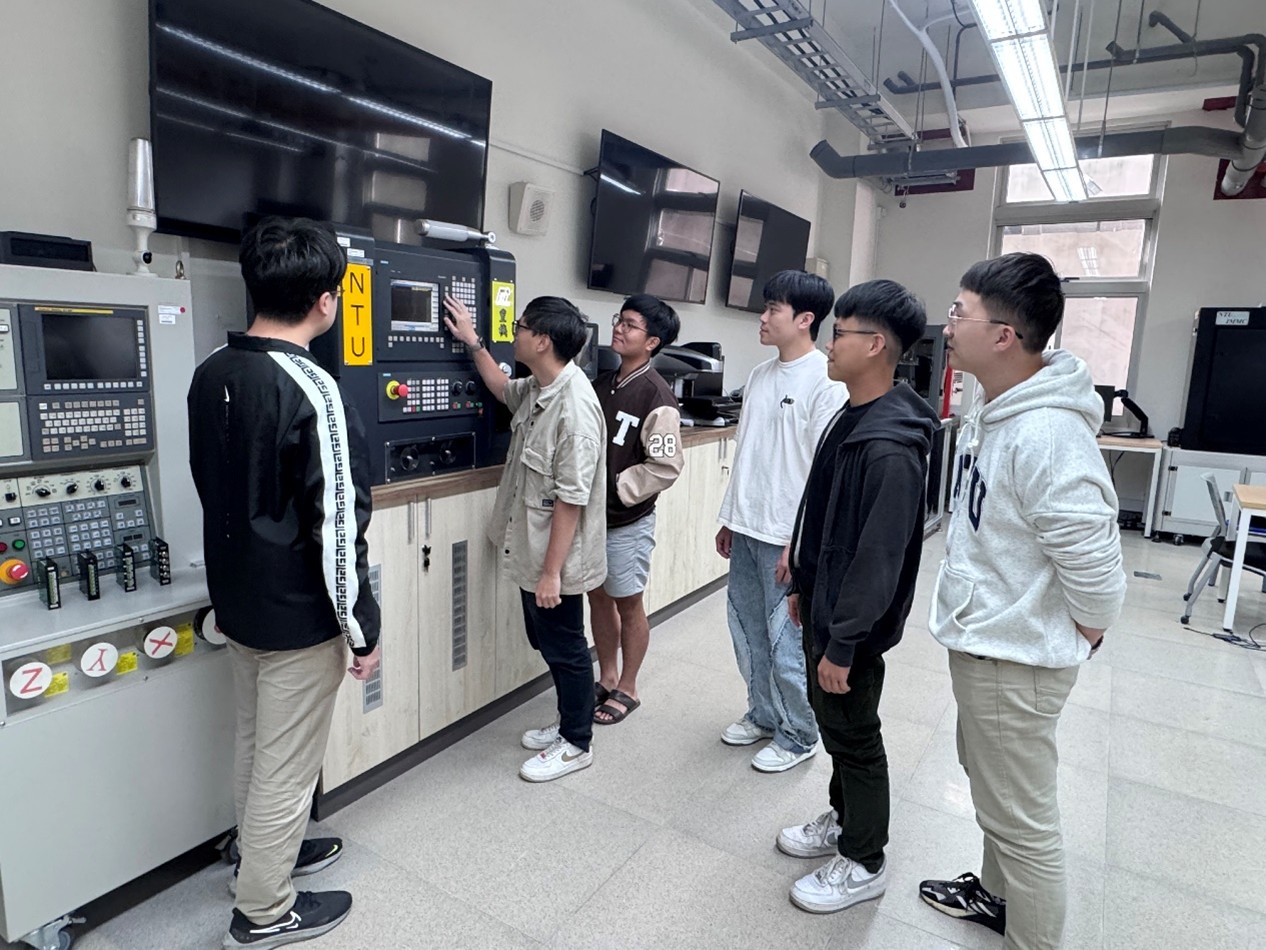

At National Taiwan University (NTU)’s Department of Mechanical Engineering, the course “Sensor Network and Data Analysis Technology for Intelligent Manufacturing” is taught by Prof. Meng-Shiun Tsai. This course offers students a robust introduction to sensor principles and machine-to-machine (M2M) networking (Figures 2 and 3). Importantly, this course provides not just essential knowledge in intelligent connectivity, but also training in applying AI and data analytics techniques to real-world smart manufacturing scenarios.

A highlight of the course is its hands-on approach to building digital twins of CNC machine tools. The students learn to integrate foundational technologies, including CAD/CAM, interpolation, servo control, transmission systems, structural dynamics, cutting process modeling, and geometric error modeling (Figure 4). These skills and technologies form the basis of building a virtual replica that mirrors the behavior of physical machines.

To enhance practical learning, the teaching team has developed a custom Edge Computing Box (ECB) that enables students to collect and analyze signals from various sensors, such as accelerometers, temperature sensors, microphones, and image sensors. The ECB is built on the Intel Edge Insights for Industrial (EII) platform and includes an OPC UA server capable of seamless communication with CNC controllers, forming a comprehensive edge AI system (Figure 5).

The Smart Manufacturing teaching team remains deeply committed to promoting AI integration in engineering education and inspiring students across disciplines to explore the rapidly evolving world of smart manufacturing. Through this course, NTU is cultivating a new generation of engineers equipped with the skills to lead in an era of intelligent automation and digital transformation.

Smart manufacturing system architecture schematic.

Teaching assistant demonstrating CNC controller functions.

Building a digital twin for CNC machine tools.

Edge Computing Box with EII platform and AI integration.